MULTI-ROW TRAILED SPRAYER

ECO TRISTAR

ECO TRISTAR

ECO TRISTAR is the series of triple-row trailed sprayers for the professional management of the chemicals applications in vineyards.

TRISTAR enables the spraying on three complete rows at the same time: three independent blowers generate the air flow in the best position, close to the vegetation, thus minimizing drift and allowing a perfect covering.

All TRISTAR sprayers are available with road homologation and hydraulic braking system.

TECHNICAL SPECIFICATIONS

TRISTAR BLOWING SYSTEM

TRISTAR blowing system is composed by a central VAC 896 Mini Target blower and two lateral specific blowers diameter 800 mm, fully in stainless steel AISI316L.

The central fan is mechanically driven, the two lateral fans are driven by an independent and cooled hydraulic circuit installed directly on the sprayer.

The blowing system is consequently fully powered by the mechanical PTO of the tractor, with very low power absorption.

SUPPORT STRUCTURE

The lateral blowers support structure is fully in AHSS Advanced High Strength Steel.

The quality of the materials, the high resistant sections and the continuous welding allow the best strength and stability.

Five double effect hydraulic rams with safety valves are used for the following functions:

- Working height adjustment;

- Opening and closing of the lateral arms;

- Row distance adjustment (variable from 2,7 to 3,1 m).

The support structure, when closed, has overall dimensions within the limits required for road circulation.

TRISTAR BLOWERS

Standard equipment of the central blower:

- Fan diameter 896 mm with 12 blades and variable pitch;

- 9+9 double no-drip nozzles on front rings;

- Low tower shape ;

- Lateral orientation of the air outlet;

- Adjustable flaps in the top.

Standard equipment of the lateral blowers:

- Fan diameter 800 mm with 9 blades and variable pitch;

- 7+7 double no-drip nozzles on front rings;

- Lateral orientation of the air outlet.

CHASSIS

Fully laser cut chassis and rear bumper in AHSS Advanced High Strength Steel.

The closed sections stringers lead to a superior strength and stability of the chassis, the rounded shape of the edges in contact with the tank prevents any possible damage to the fiberglass and grants the best reliability over the years.

The chassis, the rear bumper and all other steel parts are hot galvanized. A solid steel frame fixed to the rear part of the chassis protects the lower part of the conveyor.

TANK

- Reinforced fiberglass tank, acid-proof treatment.

- Available capacities: 2000 and 3000 litres.

- Internal tank separator on tank capacity 3000 litres.

- Spray circuit rinse tank.

- Hand-washing tank.

- Tank mixture agitator with triple flow, with total flow of 600 litres/min, allowing a perfect agitation even with dense mixtures.

- Double mixing system on tank capacity 3000 litres.

CHEMICALS CIRCUITS

- Diaphragm pump with brass heads and manifolds.

- Available flow 160/185/220/260 l/min, 50 bar.

- Possible low/medium/high spray rates (from 100 up to 10’000 l/ha).

- Suction filter and pressure filters before section valves.

- Manual or electric pressure regulator.

- Two or more nozzles section valves.

- Dump valves.

- Stainless steel chemicals pre-mixer/can rinse and Venturi chemicals suction system.

- Water suction system for tank filling with centrifugal pump.

NOZZLES AND TIPS

- Possibility to install front and rear rings of nozzles.

- 4 or 6 independent nozzles sections.

- Double or triple no-drip nozzles.

- Adjustable cone nozzles.

- Anti-drift nozzles.

TRANSMISSION

Fan gear box: 2 speed + neutral, exclusive design for our machines. Extended main body and big bearings ensure extreme reliability and long-lasting.

Synchronized transmission and pre-selection of the fan speed.

Long-life bearings drive shaft inside the tank with freewheeling. Independent hydraulic circuit for lateral fans with 70 litres cooled oil tank. Cast iron pumps, aluminium hydraulic motors with reinforced bearings for fan support.

CONTROLS

Electric remote controls box: nozzles sections,

pressure regulator, dump valves.

Electronic LCD display for tank level and spray pressure.

Automatic controller for spray rates: spray pressure,

speed, total hectares, total litres sprayed.

GPS guidance system with

spray controller interface.

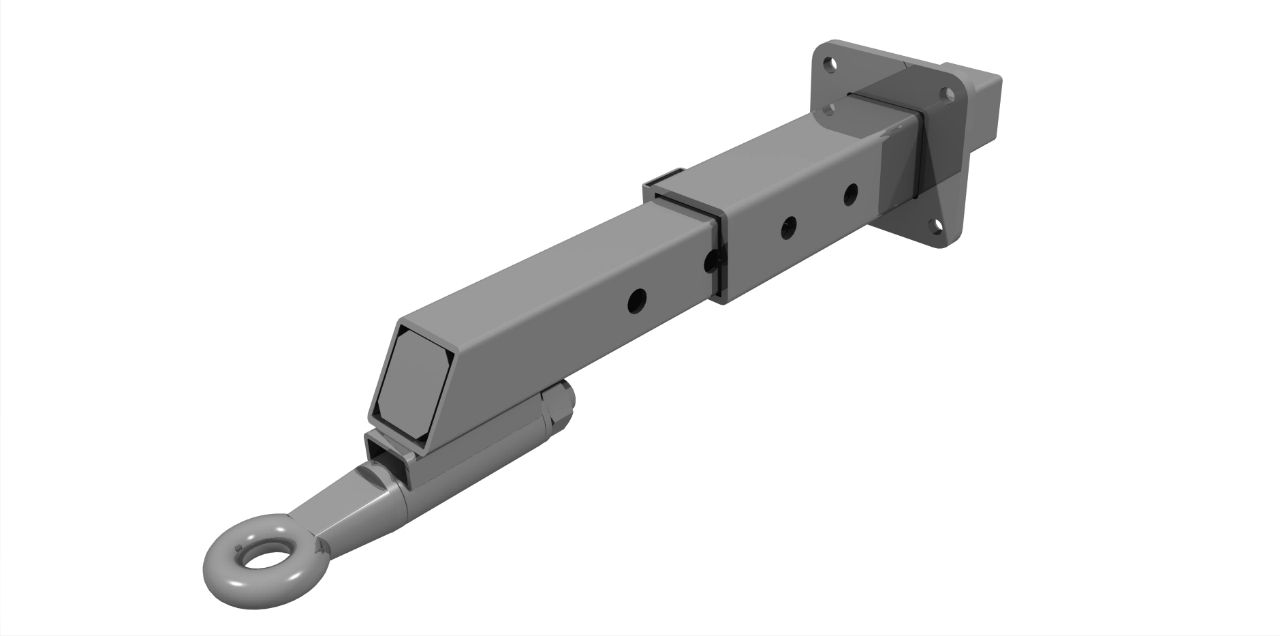

DRAWBAR

Standard drawbar, eye type, adjustable.

Steering drawbar for 3-point-linkage.

The sprayer perfectly follows tractor tracks. Sharper turns are possible. The use of a wide angle PTO shaft is advisable.

SUPERTURN steering drawbar for 3-point-linkage.

The drawbar allows constant alignment of the sprayer to tractor PTO, also when turning. The drive shaft is always straight so the tractor PTO can be always engaged, working no-stop. Standard PTO shaft can be used.

The sprayer perfectly follows tractor tracks. Very sharp turns are possible.

DIMENSIONS

| Nominal capacity | [l] | 3000 | 2000 |

| Length | [m] | 4.82 | 4.48 |

| Width (transport configuration) | [m] | 2.44 | 2.44 |

| Height | [m] | 3.55 | 3.49 |

| Fully loaded weight | [kg] | 5800 | 4600 |